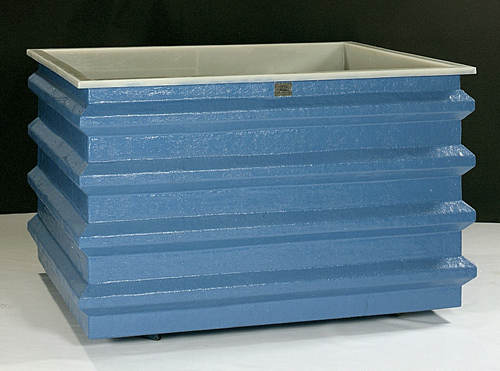

Fiberglass (FRP) Tanks

PKG Equipment Inc. distributes a line of fiberglass tanks to complement its own metal and plastic tank manufacturing capabilities. Fiberglass tanks offer reliability, longevity and corrosion resistance for the diverse storage and process needs for a wide range of industries. They are low maintenance and are ideal for acids, caustics, solvents and non-flammable corrosive fluids in plating, petroleum production, pharmaceutical, chemical, pulp and paper, wastewater treatment, and other industrial applications. They can be customized to suit various corrosive environments through the use of different types of resins, such as isothalic or vinyl ester, and are available with many optional features and accessories such as covers, legs, blending baffles, manways, skimming weirs, and other custom features to suit your equipment requirements.

In addition to straight fiberglass tanks, PKG Equipment Inc. provides dual laminate tanks. Dual laminate tanks incorporate a thermoplastic lining in a fiberglass tank to act as the primary corrosion barrier when the corrosion resistance required exceeds the limits of fiberglass. These linings, formed and welded by PKG Equipment Inc., are available in polypropylene, PVDF or Halar. The fiberglass is then bonded to the lining and creates a secondary corrosion barrier. Dual laminate tanks are a low maintenance alternative to glass, rubber or brick lined tanks.

Capabilities - Fiberglass (FRP) Tanks

- Construction

-

- One piece hand lay-up

- Materials

-

- Various resins available

- Size

-

- Cylindrical tanks up to 12′ ø

- Rectangular tanks up to 10′ long

- Resistance

-

- Corrosion

- Chemical

- Options

-

- Fittings

- Manways

- Legs

- Access ladders

- Mixer bridges

- Pumps and filters

- Heaters and controllers

- Blending baffles

- Skimming weirs

- Spray headers

- Secondary containment

- Insulation

- Tank covers

- Saddles

- Air spargers

- Linings

- PVDF

- Halar

- Polypropylene

- Sloped bottom

- Possible Applications

-

- Chemical storage

- Chemical process

- Waste treatment system

- Brine vinegar

- Plating

- Vacuum vessels

- Others