Plastisol Coating Services

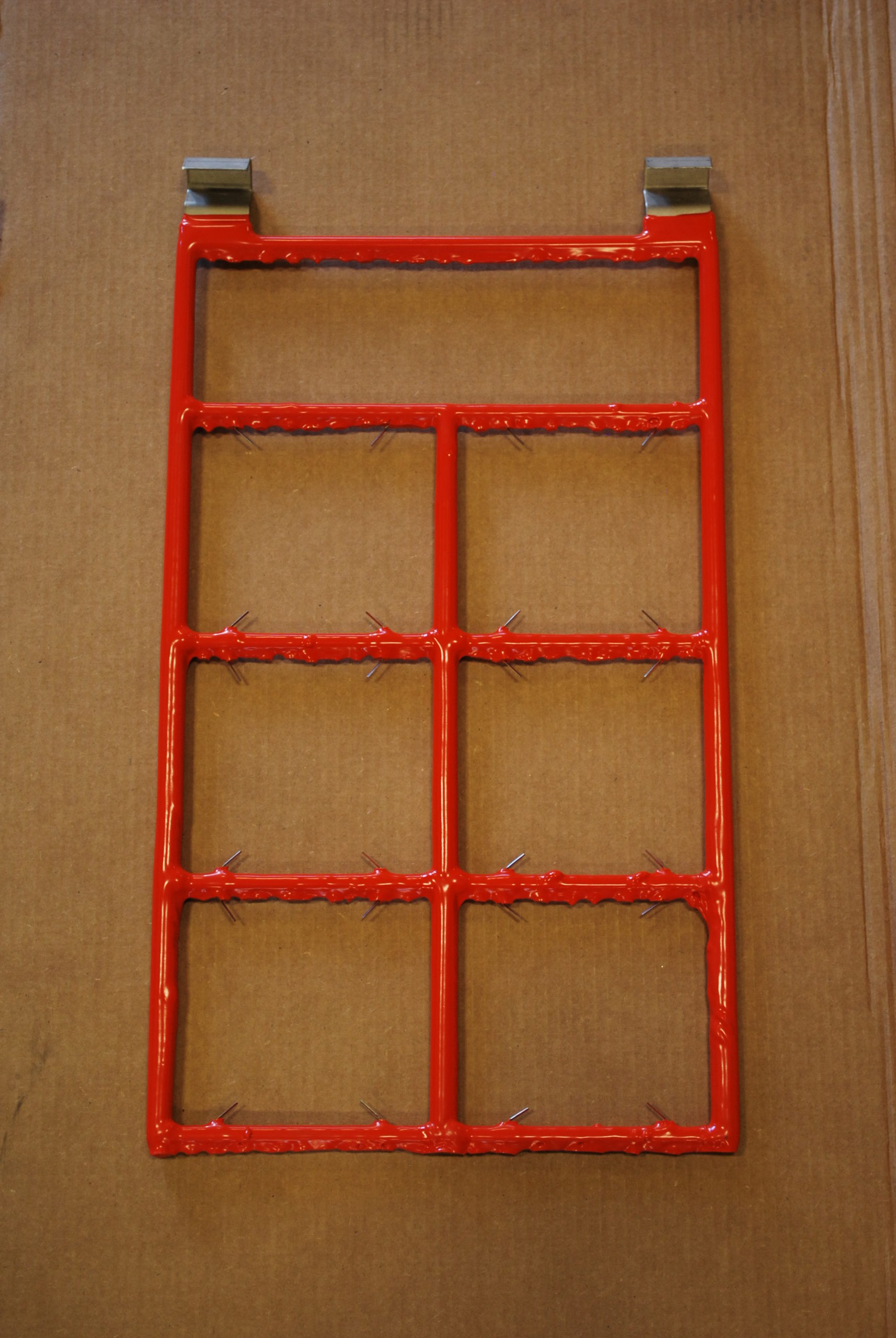

Plastisol is a dispersion of PVC resin in a liquid plasticizer. As heat is applied, the plastisol gels & fuses to become a homogenous melt. It becomes a solid as it cools with good physical properties & chemical resistance. PKG Equipment Inc. typically uses plastisol to coat plating racks, chrome plating exhaust hoods, baskets, trays, fixtures and hand grips.

Plastisols can be applied successfully to all types of metals including galvanized surfaces. Surfaces to be coated must be free of grease & oil before grit blasting. After blasting, which is done in-house, a primer must be applied to the metal where there must be adhesion. Primers would not be used if the final fused plastisol would be slipped or cut off like on slip-on tool grips. Metal parts that are primed will adhere to the fused plastisol to a bond exceeding the strength of the plastisol itself.

After priming, the metal part to be coated must be preheated to approximately 375° F. The particular temperature used will be a factor in the amount of thickness of the plastisol applied to the metal. When the part has been preheated, it is removed from the heat source & immediately dipped into the room temperature plastisol.

Green is our standard color, but other colors are available. There are several methods for plastisol coating, but PKG Equipment typically uses the dip coating method.

Capabilities - Plastisol Coating Services

- Material

-

- PVC resin in a liquid plasticizer

- Substrate

-

- Metals Including galvanized surfaces

- Surface Prep

-

- Degreasing

- Grit blasting

- Primer

- Part Preheating

-

- 375 °F

- Application Process

-

- Dipped

- Baked

- Colors

-

- Green

- Intended Applications

-

- Plating racks

- Chrome plating exhaust hoods

- Baskets

- Trays

- Conveyor fixtures