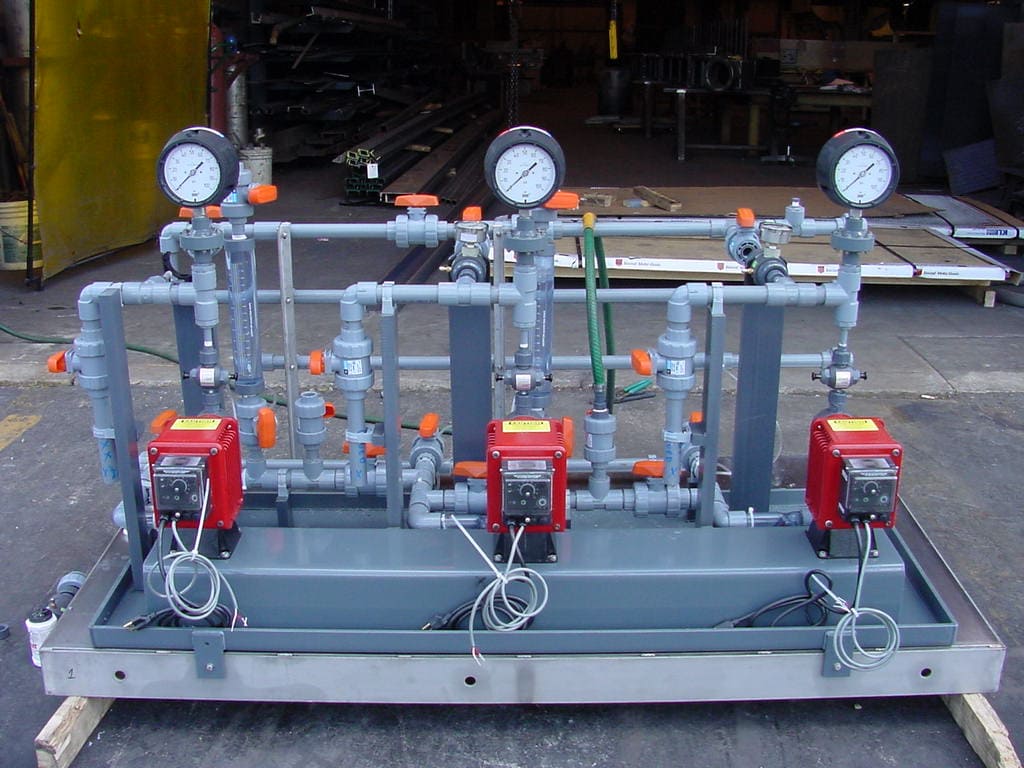

Skid Mounted Process Systems

At PKG Equipment Inc., we specialize in the design, fabrication, and installation of industrial process equipment. To answer the needs of our growing customer base, we offer custom skid mounted process systems.

Modern manufacturing operations demand innovative solutions to add value and operational flexibility to capital equipment purchases. Our modular approach is driven by this need with systems that are developed, manufactured, and integrated from the ground up with flexibility, simple operation and changeover in mind. Mobility is aided by the judicious use of carbon, stainless, and alloy steels or lightweight materials such as thermoplastics. Equipment is designed to seamlessly integrate into existing systems with easy to install features such as single connection points for mechanical and electrical connections. Systems can include components such as pumps, valves, heat exchangers, control panels, complete instrumentation, and custom tanks. From simple pumping stations to complex automation, every system is custom fabricated to meet individual customer requirements.

Equipment can be fabricated with the operational advantages of automation, which can provide enhanced production, quality, increased operator safety, and deliver traceability and centralized control. We offer systems that utilize advanced PLC or PC based control systems with custom programmed state of the art software that can be fully integrated into your network.

UL508 listed control panels are also available, as well as control panels geared for operation in hazardous locations. We deliver true turnkey solutions, which may include documentation and training, as well as service after the sale. To learn more about our custom skid mounted process systems, see the table below or contact PKG Equipment directly.

Capabilities - Skid Mounted Process Systems

- General Capabilities

-

- Design

- Fabrication

- Installation

- Automation network integration

- System Benefits

-

- Custom built

- Reduce field installation labor

- Solitary connection point for mechanical & electrical

- Improved system integration; facilitates expansion

- Systems shipped pre-assembled and pre-tested

- Easy maintenance access to system and components

- Resistance

-

- Corrosion

- System Capabilities

-

- Blending

- Filtration

- Monitoring

- Chemical feed

- Heating

- Pumping

- Cooling

- Automation

-

- Full turn-key systems from design to start-up

- UL508 listed control panels at customers’ request

- System wiring to NEC specification

- PLC or PC based controls, utilizing:

- Allen Bradley Factory Talk Platform

- RSLogix

- Wonderware

- Automation Benefits

-

- Increase production rates

- Reduce production costs

- Improve quality

- Increase operator safety

- Increase consistency

- Adds traceability

- Centralize control of the system

- Custom Control Panels

-

- Provide simple instrumentation to a complete PLC based control system

- Panel design for the most efficient control performance

- Instrumentation integration for your system

- UL 508 A Certification for the United States & Canada when requested

- Accompanied by complete documentation

- Data collection and logging

- Hazardous location design and implementation

- Onsite installation, upgrade, and debugging services

- Instrumentation

-

- Temperature

- pH

- Flow

- Liquid level

- Concentration

- Conductivity

- Additional Services

-

- Thermal & mechanical design

- Process piping

- Equipment modifications

- Equipment relocation

- Field service & repairs