Process & Storage Tanks

PKG Equipment Inc. provides industrial tank design and fabrication services that have made us an industry leader. From project design and coordination to fabrication and field installation, our services will supply you with a tank that is designed to suit your application. Our carbon steel, stainless steel, fiberglass, and plastic tanks can meet the needs of most wet or dry bulk storage and processing applications.

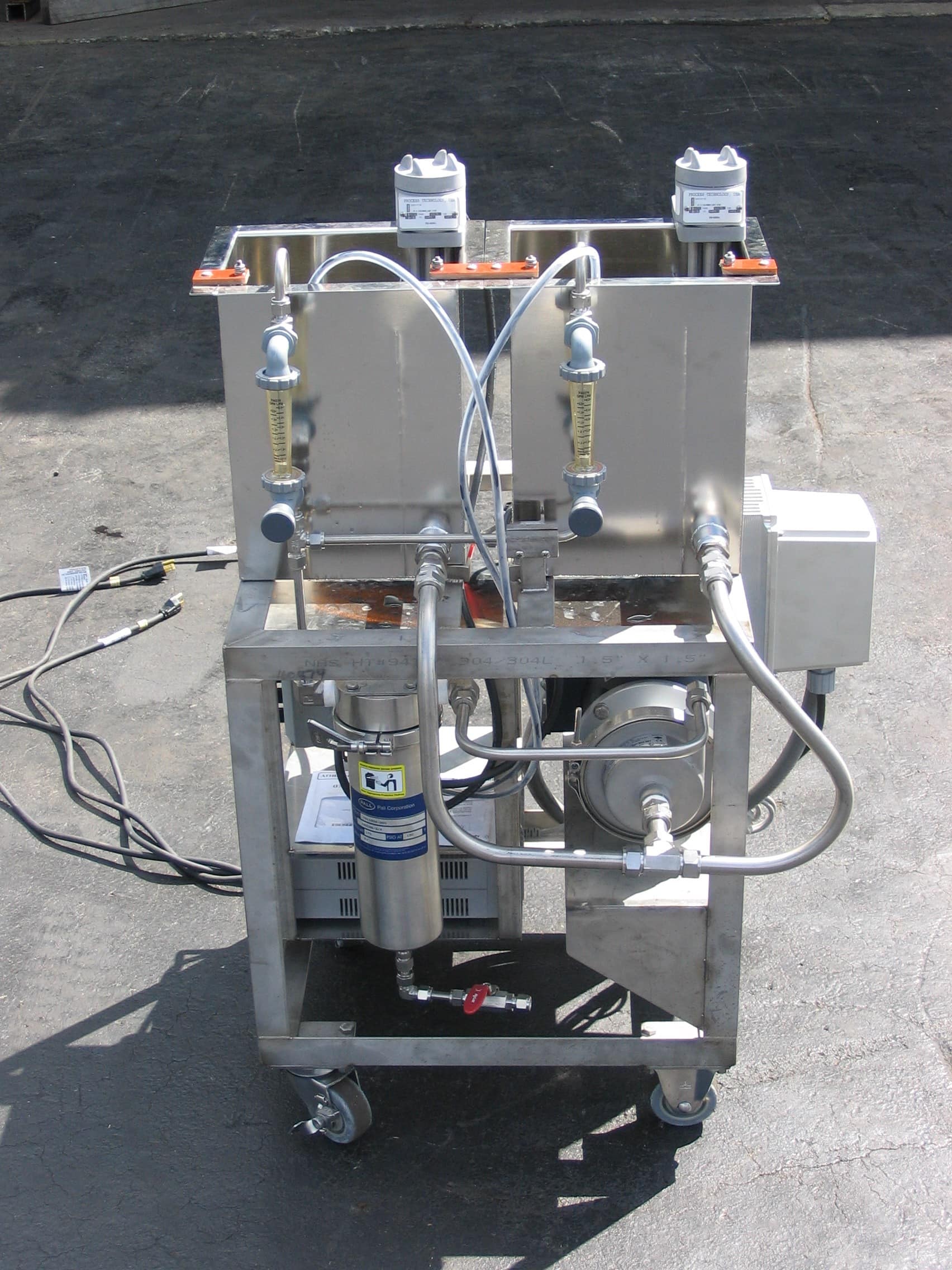

Our expertise is extensive, fabricating tanks in various shapes and sizes for use in above ground storage, secondary containment, waste treatment, chemical processing, and plating line applications, just to name a few. Our plastic tanks are custom fabricated by using butt welders and forming machines, minimizing hand welding as much as possible, to produce stronger, more durable tanks. In addition to fabricating our own custom plastic tanks, we are a distributor of molded XLPE and HDPE tanks in different configurations and sizes up to 14,000 gallons. Our metal tank fabrication capabilities include ASME Code tanks, pressure vessels and columns. These are typically fabricated from carbon steel or stainless steel, but specialty metals are available. Depending on your particular needs, tanks can be fitted with a wide variety of tank liners and may be supplied with options such as instrumentation for measuring and monitoring process parameters, bussing, spray headers, secondary containment, mixer bridges, pumps, heaters, and many other custom features and components.

To ensure top quality, our plastic fabricators are ASTM C1147 qualified and welders are ASME Section 9 qualified. Our industrial tank design, fabrication, and installation capabilities, fully described below, offer you the efficiency and convenience to single-source your industrial tank fabrication needs.

Learn More About Specific Process & Storage Tanks

Capabilities - Process & Storage Tanks

- General Capabilities

-

- Design

- Fabrication

- Installation

- Types of Tanks

-

- Above ground storage

- Anodizing

- ASME Code

- API 650

- Black oxide

- Chemical

- Chromating

- Cleaning

- Corrosion resistant

- Double wall

- Electrocoating

- Etching

- Galvanizing

- Lethal service

- Non-code

- Phosphating

- Pickling

- Plating

- Secondary containment

- Storage

- Waste treatment

- Wire processing

- Construction Material

-

- Carbon steel

- Stainless steel

- Specialty metals

- Polypropylene

- HDPE

- PVC

- CPVC

- PVDF

- Teflon

- Fiberglass

- Configuration

-

- Rectangular

- Cylindrical

- Cone bottom

- Dished bottom

- Sloped bottom

- “V” bottom

- Horizontal

- Vertical

- Options

-

- Fittings

- Manways

- Tank stands

- Ladders

- Secondary containment

- Insulation with jacket

- Bussing

- Saddles

- Mixer bridges

- Flexible or rigid liners

- Tank linings

- Pumps and filters

- Spray headers

- Air spargers

- Covers

- Blending baffles

- Heaters and controllers

- Skimming weirs

- Coatings and linings

- Other custom features

- Instrumentation

-

- Temperature

- pH

- Flow

- Liquid level

- Concentration

- Conductivity

- Other Equipment and Services

-

- Tank lining

- Tank repair

- Tank modifications

- Tank inspections

- Tank relocation

- Process piping

- Thermal & mechanical design