PKG Equipment Contributes to Article in Cutting Tool Engineering.

Comments Off on PKG Equipment Contributes to Article in Cutting Tool Engineering.Bringing out-sourced services in-house can help companies increase sales opportunities, shorten lead times, reduce product costs, and improve quality control. Success stories are detailed in the article along with things to consider when exploring the addition of value-added services to your operations. The decision to bring traditionally outsourced services in-house can be an expensive and […]

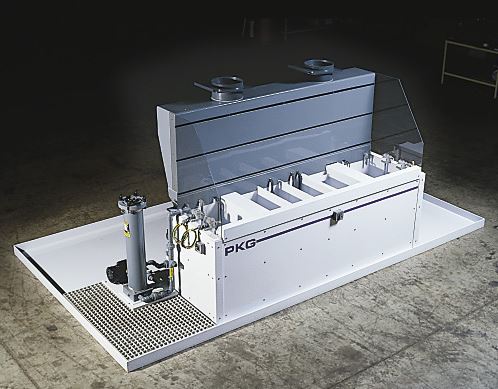

Making Plating Lines New Again

Comments Off on Making Plating Lines New AgainPKG Equipment helps Monroe Plating in Rochester, New York revive a used line to expand their operations. Monroe Plating began looking at adding capacity, which meant expanding its operation and adding a finishing line. John Rowe has never thought of himself as a “new car” kind of guy, preferring instead to kick the tires of […]

PKG Equipment in Rochester Business Journal

Comments Off on PKG Equipment in Rochester Business JournalPKG Equipment Inc. is increasing its capabilities, physical size and workforce. The Chili firm has invested more than $1 million in more space and equipment to keep pace with growth. The facility added roughly 15,000 square feet to their building and are now at 50,000 square feet. Increased capabilities, a more diversified customer base, and […]

PKG Equipment Inc. and Roberts Chemical Co., Inc. Form New Partnership

Comments Off on PKG Equipment Inc. and Roberts Chemical Co., Inc. Form New PartnershipPKG Equipment Inc., a process equipment manufacturer specializing in surface finishing equipment, has formed a strategic alliance with Roberts Chemical Co., Inc. of Attleboro, Massachusetts, a full service chemical distributor for the Northeastern U.S. PKG Equipment will be representing Roberts Chemical Co., and Roberts Chemical Co. will be a distributor for PKG Equipment covering the […]

PKG Equipment Enhances Plastic Fabricating Capabilities

Comments Off on PKG Equipment Enhances Plastic Fabricating CapabilitiesPKG Equipment installed a third thermoplastic sheet butt welding machine in its plastic fabrication department with several advanced technological features. The butt welder has sheet thickness capacities that range from 1/8″ to 2-3/8″ with a working width of 158″. It can also be used to butt weld 90° corners on material over 1/2″ thick. The […]

PKG Equipment Installs New Miller Submerged Arc Welding System

Comments Off on PKG Equipment Installs New Miller Submerged Arc Welding SystemPKG Equipment recently installed a new Miller submerged arc welding system to expand its capabilities in the fabrication of process equipment. This sumerged arc welder uses a continuously fed consumable solid or tubular (flux cored) electrode. The molten weld and the arc zone are protected from atmospheric contamination by being “submerged” under a blanket of […]

PKG Equipment Inc. Receives Exclusive Authorization to use HY-PRO® for Plastic Fabrications

Comments Off on PKG Equipment Inc. Receives Exclusive Authorization to use HY-PRO® for Plastic FabricationsPKG Equipment Inc. has just received exclusive authorization to use HY-PRO® flame retardant clad polypropylene to manufacture process equipment. PKG Equipment has been fabricating process equipment from various thermoplastics for over 30 years, but this new capability allows PKG to offer plastic fabrications that require some flame retardant provisions without the expense associated with solid […]